| OCP 2.8 Quick Start Guide |

OCP is a program to optimize the cutting of linear material . It will take a list of stock and/or orderable material to cut and determine cutting lists which minimize the amount of scrap material. OCP generates a cutting list report along with the amount of stock used and provides the ability to mix orderable material with current stock and generate an optimal order list as well as a cutting list. Click to Print these instructions.

This guide includes:

- Program Setup

- Steps for Creating a Cutting Project

- Sample On-Screen Cutting Report

- Handy Tips for Performance

- Adding Material Types

- Open File Format Definition

- Command line interface

Program Setup |

1. Choose OCP from your computer's Start / Programs menu

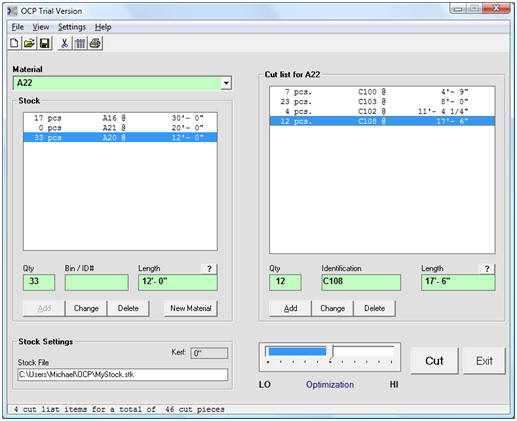

Figure 1 - OCP Main Screen

1.1 Enter a small description for the type of material at the top of the Stock area. This acts as a filter so you only see stock and cuts for the material type displayed.

2. Choose Settings / Program from the Pull-down Menu on the Main Screen

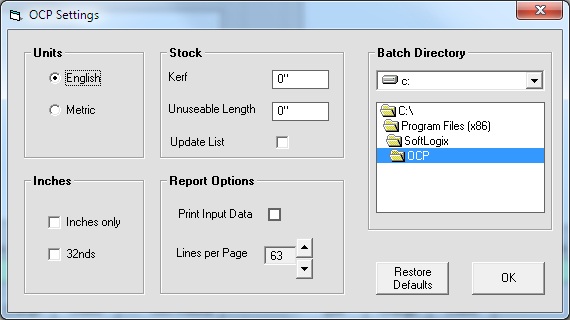

Figure 2 - The Settings Dialog

2.1 Select Units of Measurement

|

Units |

|

|

English |

feet, inches, sixteenths: Example: |

|

Metric |

All lengths are in millimeters. |

2.2 Stock

Set kerf to the length of material that is lost from a single cut.

Set Un-useable length to a value equal to the length of stock that is not available for cutting. This is useful if stock ends need to be shortened due to end damage or if saw measurements must start a certain distance from the end.

Choose update if the stock list should be updated after cutting. The stock material is automatically saved and the quantity updated.

2.3 Report Options

Choose 'Print Input Data on Report' if the cutting report should include the original stock and material list used for the cutting process.

2.4 Close the Settings Dialog

You are now ready to start a cutting project.

Steps for Creating a Cutting Project |

- From the FILE menu choose NEW

- Enter the type of material in the 'Material Type' pick list box.

- Enter in the stock material quantity and lengths . Use a quantity of zero if the stock size is to be ordered. Using the Bin/ID# field is optional. If you do not use it a sequential ID# is created so you can identify the stock in the cutting list with the stock items.

- Type in the cutting list (tool tips will appear to help you if needed)

- Choose File/Save . Choose or create a directory for the cutting project and type in a file name. No extension is necessary. The name you enter becomes the stock filename with a .stk extension. A cutting file with the same name is automatically created with a .cut extension.

- You may now cut the material or enter data for a different material type. To cut the current material proceed to step 7. To add data for a different material go to Step 2.

- Choose the material Type you wish to cut in the 'Material Type' Pick List and Press 'Cut'

- Wait as OCP performs optimal cutting. This may take anywhere from seconds to hours (depending on the complexity and the optimization setting). The progress bar may appear to stop. This is normal as OCP is in deep thought. Use your computer for other things if cutting takes a long time. To abort the computation just press 'Cancel' in the Cutting Progress indicator. Abort may take a few seconds to a good part of a minute to occur. If you abort, the cutting report will only show pieces cut up until the time cutting was interrupted. Proceed to step 9.

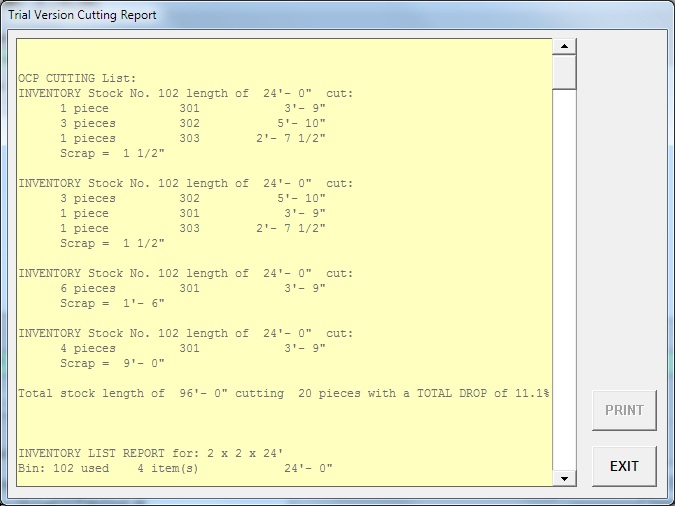

- A cutting report is displayed automatically when cutting is complete.

- To improve the cutting optimization slide the Optimization lever to the right. Note: This does not guarantee an improvement.

- To reduce the computation time slide the Optimization lever to the left

-

To cut again go to step 2 to add more data or step 7 to choose a different material type.

Adding Material Types |

- Change the text in the Material pick list box. This acts as a filter so that only the material type in this box is displayed.

- Enter the stock and cuts for this material type

- Choose File / Save and save the project.

- Choose File / Open to re-open the project.

- Use the Material Pick-list control to select which material type is active.

Sample On-Screen Cutting Report |

Handy Tips for Performance |

- Faster processors reduce computation times. Computation times are typically less than a few minutes when cutting a few hundred pieces.

- To speed up cutting you may set the Optimization control to a lower setting. This may be done during cutting or before cutting computation begins. You may cancel cutting at any time by pressing the 'Cancel' button in the Cutting Progress dialog and waiting for the program to give you control. You can then adjust the Optimization Control and cut again.

- Cutting may be quicker when the range between the longest and shortest cut length is smaller. That is, cutting 2 foot pieces and 50 foot pieces in the same project may contribute to longer computation times.

- OCP may not provide much advantage for problems that can be solved quickly by humans. OCP proceeds as though every cut is a different length and so there may be a more significant computation time when many cuts are the same length..

File Formats |

Stock file

Space, semicolon or comma delimited. First line contains the field names. Length are interpreted either in millimeters or decimal feet. This is determined by the setting in the OCP Settings Program menu.

Each line is enclosed in double quotation " marks.Filename: *.stk

"MARK(bin) MATERIAL QTY LENGTH"

"001;C100*50;1;5245"

Cut file

Space, semicolon or comma delimited. First line contains the field names.

Each line is enclosed in double quotation marks.Filename: *.cut

" MARK MATERIAL QTY LENGTH"

"X8B61-1003 C100*50 2 1538"

Export file

- File name: export.txt is generated by default in the OCP installation directory - such as C:\Program Files\ OCP

- First line contains the field names

- Example comma delimited file below (units in mms)

- "Status, Stock#, Material, Length, Mark, Cut"

"INVENTORY, 1, C100*50, 6000, 6B11-1019 ,5878"

"NON-INVENTORY, 2, C100*50, 6000, 6B11-1019 ,5878"

"SCRAP, 1, UB254*102*22, 900"

Command Line Interface |

>ocp.exe cut_file.cut stock_file.stk output_file.txt shape kerf

where:

cut_file = cut filename

stock_file.stk = stock filename

output_file.txt = output cutting list filename

shape = material description. This must match a material description within the stock and cut files. No spaces are allowed in the description.

kerf = length of material lost due to cutting

OCP will process the above file set using file data with the specified shape. Repeated batch calls to OCP.exe with different shapes can process different material shapes within the same stock and cut files.

Program Specifications

Specifications OCP Trial Version OCP Ver 2.8 Interfaces keyboard keyboard & universal file export Capacity 3 stock sizes

6 cut sizes &

50 cuts100 stock sizes

100 stock pcs. + orderable lengths

500 cut sizes &

2000 cut pcs.Reports on-screen cutting list Printed Cutting & Order Lists

NOTICE / DISCLAIMER:

THE LICENSE IS EFFECTIVE UNTIL TERMINATED. YOU MAY TERMINATE THE LICENSE AT ANY TIME BY DESTROYING ALL COPIES OF THE PROGRAM AND ITS DOCUMENTATION. YOU MAY NOT USE, COPY, MODIFY OR DISTRIBUTE THE REGISTERED PROGRAM OR DOCUMENTATION OR ANY COPY, MODIFICATION OR PORTION OF THE PROGRAM OR DOCUMENTATION EXCEPT AS EXPRESSLY PROVIDED FOR IN THIS DOCUMENT. VIOLATION OF ANY LICENSE PROVISION AUTOMATICALLY TERMINATES YOUR LICENSE AND MAY SUBJECT YOU TO CIVIL AND/OR CRIMINAL LIABILITY.

THIS PROGRAM IS PROVIDED "AS IS" WITH NO WARRANTY, OTHER THAN ITS STATED FUNCTION, EITHER EXPRESSED OR IMPLIED INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE ENTIRE RISK AS TO THE SUITABILITY, QUALITY AND PERFORMANCE OF THE PROGRAM IS WITH THE LICENSEE.

IN NO EVENT WILL SOFTLOGIX, INC. BE LIABLE TO YOU OR ANY OTHER PARTY FOR ANY DAMAGES, INCLUDING LOST PROFITS AND/OR ANY OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO USE THE PROGRAM EVEN IF SOFTLOGIX, INC. HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

| Windows® XP and Windows Vista™ are trademarks of Microsoft Corporation. |